|

|

45ΜG

45MG Ultrasonic Thickness Gage:

Το 45MG, αποτελεί καινοτόμος προσθήκη στην γκάμα παχυμέτρων με υπερήχους της Olympus-NDT, αφού εξασφαλίζει στο χρήστη τη δυνατότητα άμεσης αναβάθμισης του οργάνου, με την παραγγελία του ή και μελλοντικά χωρίς να απαιτείται επιστροφή του στον κατασκευαστή, προσθέτοντας του όποια ή όλες από τις παρακάτω προαιρετικές δυνατότητες απαιτούνται για την/τις εφαρμογή/ες:

- Αποθήκευση και ανάκληση των μετρήσεων μαζί με λογισμικό για αμφίδρομη επικοινωνία με Η/Y

- Δυνατότητα μέτρησης βαμμένου μετάλλου, αγνοώντας το πάχος της μπογιάς ή ακόμη και προβάλλοντας ταυτόχρονα το πάχος του μετάλλου και το πάχος της μπογιάς με χρήση των κατάλληλων αισθητήρων

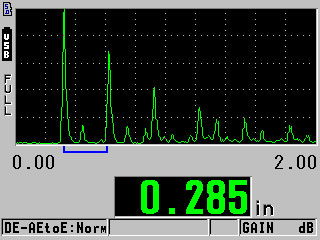

- Απεικόνιση κυματομορφής A-Scan

- Λειτουργία του παχυμέτρου με αισθητήρες μονού κρυστάλλου (Precision Thickness Gage)

- Υψηλή διείσδυση (high penetration)

Σε ό,τι αφορά τα προηγμένα στάνταρ χαρακτηριστικά του 45MG:

- Πρόκειται για εξαιρετικά ανθεκτικό όργανο, ειδικά κατασκευασμένο και πιστοποιημένο για χρήση σε αντίξοες συνθήκες, εφόσον ο βαθμός προστασίας του 45MG ως προς International Protection Rating είναι IP67

- Εξαιρετικά εύχρηστο, μπορεί να χρησιμοποιηθεί από αριστερόχειρες ή δεξιόχειρες, άμεσος έλεγχος λειτουργιών, έγχρωμη οθόνη (Color Transflective QVGA) με δυνατότητα εναλλαγής χρωμάτων για χρήση σε εσωτερικούς ή εξωτερικούς χώρους .

- Time-based B-scan για γρήγορη προβολή των εναλλαγών πάχους κατά μήκος μίας επιφάνειας

- Min./Max. Mode

- Δύο Alarm modes

45MG Χαρακτηριστικά

| Measurements | |

| Dual element transducer measurement mode | Time interval from a precision delay after the excitation pulse to the first echo |

| Echo-to-Echo (optional) | Time interval between two successive back-wall echoes to eliminate paint or coating thickness |

| THRU-COAT® measurement (optional) | Measurement of true metal and coating thicknesses with a single back-wall echo (with D7906-SM, D7906-RM, and D7908 transducers) |

| Single element transducer measurement modes (optional) | Mode 1: Time interval between the excitation pulse and the first back-wall echo Mode 2: Time interval between the delay line echo and the first back-wall echo (with delay or immersion transducers) Mode 3: Time interval between successive back-wall echoes following the first interface echo after the excitation pulse (with delay line or immersion transducers) |

| Thickness range | 0.080 mm to 635 mm (0.003 in. to 25.0 in.) depending on material, transducer, surface conditions temperature, and selected configuration (Full range requires single element option) |

| Material velocity range | 0.508 mm/μs to18.699 mm/μs (0.020 in./μs to 0.7362 in./μs) |

| Resolution (selectable) | Low: 0.1 mm (0.01 in.) Standard: 0.01 mm (0.001 in.) Single Element option: 0.001 mm (0.0001 in.) |

| Transducer frequency range | Standard: 2.25 MHz to 30 MHz (-3 dB) High Penetration (Single Element option): 0.50 MHz to 30 MHz (-3 dB) |

| General | |

| Operating temperature range | -10 °C to 50 °C (14 °F to 122 °F) |

| Keypad | Sealed, color-coded keypad with tactile and audible feedback |

| Case | Impact-resistant and water-resistant, gasketed case with sealed connectors. Designed for IP67. |

| Dimensions (W x H x D) | Overall: 91.1 mm x 162 mm x 41.1 mm (3.59 in. x 6.38 in. x 1.62 in) |

| Weight | 430.9 g (0.95 lb) |

| Power Supply | 3 AA batteries/USB power supply |

| Battery life operating time | 3 AA alkaline: 20 to 21 hours 3 AA NiMH: 22 to 23 hours AA Lithium: 35 to 36 hours |

| Standards | Designed for EN15317 |

| Display | |

| Color transflective QVGA display | Liquid crystal display, display area 54.61 mm x 41.15 mm (2.15 in. x 1.62 in.) |

| Rectification | Full wave, RF, half-wave positive, or half-wave negative (Waveform option) |

| Inputs/Outputs | |

| USB | 2.0 client |

| Memory card | Maximum capacity: 2 GB removable MicroSD memory card |

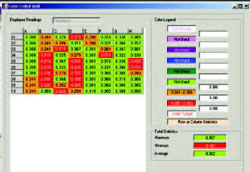

| Internal Data Logger (Optional) | |

| Data logger | The 45MG identifies, stores, recalls, clears, and transmits thickness readings, waveform images, and gage configuration information through USB or MicroSD. |

| Capacity | 475,000 thickness measurements or 20,000 waveforms with thickness measurements |

| File names, IDs, and comments | 32-character file names and 20-character alphanumeric location codes with four comments per location |

| File structure | Six standard or custom application-specific file structures |

| Reports | On-gage reporting of summary with statistics, Min./Max. |

Standard Package

- 45MG digital ultrasonic thickness gage

- AA alkaline batteries

- 2-step test block and couplant

- USB cable

- User's manual on CD

- Measurement features: Min./Max. mode, two alarm modes, Differential, mode, B-scan, Reduction Rate, Programmable Lock

Software Options

- 45MG-SE (U8147022): Single Element option to use single element transducers with frequency range of 2.25 MHz to 30 MHz.

- 45MG-HP (U8147023): Single Element High Penetration option to use single element transducers with frequency range of 0.5 MHz to 30 MHz.

- 45MG-EETC (U8147021): Echo-to-Echo and THRU-COAT®

- 45MG-WF (U8147019): Waveform option

- 45MG-DL(U8147020): Internal data logger including GageView interface program

Optional Accessories

- MICROSSD-ADP-2GB (U8779307): 2 GB External MicroSD memory card

- 45MG-RPC (U8779676): Rubber protective boot with stand

Dual Element Transducers for Corrosion Gaging

All standard dual element transducers feature Automatic Probe Recognition, which automatically recalls a default V-path correction for each specific transducer.

| Item Number | Part Code | Freq. (MHz) | Connector Type | Connector Location | Range in Steel (mm) | Range in Steel (in) | Temperature Range °F | Temperature Range °C | Tip Diam. (mm) | Tip Diam. (in) |

D792 | 10 | Potted | Straight | 0.5 - 25 | 0.020 - 1 | 32 - 122 | 0 - 50 | 7.2 | 0.283 | |

D793 | 10 | Potted | Right Angle | 0.5 - 25 | 0.020 - 1 | 32 - 122 | 0 - 50 | 7.2 | 0.283 | |

D798 | 7.5 | Potted | Right Angle | 0.71 - 100 | 0.028 - 4 | -5 - 300 | -20 - 150 | 7.2 | 0.283 | |

D798-LF | 7.5 | Potted | Right Angle | 0.71 - 100 | 0.028 - 4 | -5 - 300 | -20 - 150 | 8.9 | 0.35 | |

D798-SM | 7.5 | Microdot | Straight | 0.71 - 100 | 0.028 - 4 | -5 - 300 | -20 - 150 | 7.2 | 0.283 | |

D7226 | 7.5 | Potted | Right Angle | 0.71 - 100 | 0.028 - 4 | -5 - 300 | -20 - 150 | 8.9 | 0.35 | |

D799 | 5 | Potted | Right Angle | 1.0 - 508 | 0.040 - 20 | -5 - 300 | -20 - 150 | 11 | 0.434 | |

D791-RM | 5 | Microdot | Right Angle | 1.0 - 508 | 0.040 - 20 | -5 - 752 | -20 - 400 | 11 | 0.434 | |

D790-SL | 5 | LEMO | Straight | 1.0 - 508 | 0.040 - 20 | -5 - 932 | -20 - 500 | 11 | 0.434 | |

D790-SM | 5 | Microdot | Straight | 1.0 - 508 | 0.040 - 20 | -5 - 932 | -20 - 500 | 11 | 0.434 | |

D790-RL | 5 | LEMO | Right Angle | 1.0 - 508 | 0.040 - 20 | -5 - 932 | -20 - 500 | 11 | 0.434 | |

D790 | 5 | Potted | Straight | 1.0 - 508 | 0.040 - 20 | -5 - 932 | -20 - 500 | 11 | 0.434 | |

MTD705 | 5 | Lepra/Con | Right Angle | 1.0 - 19 | 0.040 - 0.75 | 32 - 122 | 0 - 50 | 5.1 | 0.200 | |

D791 | 5 | Potted | Right Angle | 1.0 - 508 | 0.040 - 20 | -5 - 932 | -20 - 500 | 11 | 0.434 | |

D794 | 5 | Potted | Straight | 0.75 - 50 | 0.030 - 2 | 32 - 122 | 0 - 50 | 7.2 | 0.283 | |

D797-SM | 2 | Microdot | Straight | 3.5 - 635 | 0.150 - 25 | -5 - 752 | -20 - 400 | 22.9 | 0.900 | |

D797 | 2 | Potted | Right Angle | 3.5 - 635 | 0.150 - 25 | -5 - 752 | -20 - 400 | 22.9 | 0.900 |

Single Element Transducers for Precision Thickness Measurements

Contact Transducers

| Frequency | Element Diameter | Transducers | Item Number | |

| mm | inches | |||

| 0.5 | 25 | 1.00 | M101-SB* | U8400017 |

| 1.0 | 25 | 1.00 | M102-SB* | U8400018 |

| 1.0 | 13 | 0.5 | M103-SB* | U8400020 |

| 2.25 | 13 | 0.5 | M106-RM | U8400023 |

| M106-SM | U8400025 | |||

| 2.25 | 13 | 0.5 | M1036 | U8400020 |

5.0 | 13 | 0.5 | M109-RM | U8400027 |

| M109-SM | U8400028 | |||

| 5.0 | 6 | 0.25 | M110-RM | U8400030 |

| M110-SM M110H-RM** | U8400031 U8400029 | |||

| 10 | 6 | 0.25 | M112-RM M112-SM | U8400034 U8400035 U8400033 |

| M112H-RM** | U8400033 | |||

| 10 | 3 | 0.125 | M1016 | U8400015 |

| 20 | 3 | 0.125 | M116-RM | U8400038 |

| M116-SM | U8400039 | |||

| 20 | 3 | 0.125 | M116H-RM** | U8400037 |

*These transducers can only be used with the High Penetration software option.

**Use with spring loaded holder.

Sonopen® Transducers

The Sonopen transducer has a replaceable delay line that is tapered to a small contact area. This transducer makes reliable thickness measurements in applications such as turbine blades and tight radii on plastic containers.

Sonopen - 15 MHz, 3 mm (0.125 in.) transducer

| Straight Handle | Right Angle Handle | 45° Handle | |||

| Part | Item Number | Part | Item Number | Part | Item Number |

| V260-SM | U8411019 | V260-RM | U8411018 | V260-45 | U8411017 |

Sonopen - Replaceable Delay Lines

| Tip Diameter | Part | Item Number | |

| mm | inches | ||

| 2.0 | 0.080 | DLP-3 | U8770086 |

| 1.5 | 0.060 | DLP-302 | U8770088 |

| 2.0 | 0.080 | DLP-301† | U8770087 |

†High temperature delay for use up to 175°C (350°F)

Immersion Transducers

Panametrics Microscan immersion transducers are designed to transmit and receive ultrasound in water. Thickness measurements by immersion technique are often preferred when the test piece has a complex geometry or in on-line applications. Typical off-line applications include wall thickness measurements on small diameter plastic or metal tubing, scanned or rotary measurements and thickness measurements on sharply curved parts. Transducer focusing may be necessary depending on the application.

| Frequency (MHz) | Element Diameter | Transducer |

| |

| mm | in. | |||

| 2.25 | 13 | 0.50 | M306-SU | U8410027 |

| 5.0 | 13 | 0.50 | M309-SU | U8420001 |

| 5.0 | 6 | 0.25 | M310-SU | U8420004 |

| 10 | 6 | 0.25 | M312-SU | U8420008 |

| 15 | 6 | 0.25 | M313-SU | U8420009 |

| 20 | 3 | 0.125 | M316-SU | U8420011 |

RBS-1 Immersion Tank

The RBS-1 immersion tank is designed to simplify ultrasonic thickness measurements using immersion techniques.

Delay Line Transducers

Microscan delay line transducers provide excellent performance on very thin materials, at elevated temperatures,or with applications that require a high degree of thickness resolution.

| Freq. (MHz) | Element Diameter | Transducer |

| Holders | Item Number | |

| mm | inches | |||||

| 0.5 | 25 | 1.00 | M2008* | U8415001 | - | - |

| 2.25 | 13 | 0.50 | M207-RB | U8410017 | - | - |

| 5.0 | 13 | 0.50 | M206-RB | U8410016 | - | - |

| 5.0 | 6 | 0.25 | M201-RM | U8410001 | - | - |

| 5.0 | 6 | 0.25 | M201H-RM | U8411030 | 2127 | U8770408 |

10 | 6 | 0.25 | M202-RM | U8410003 | - | - |

| M202-SM | U8410004 | |||||

| 10 | 6 | 0.25 | M202H-RM | U8507023 | 2127 | U8770408 |

10 |

| 0.125 | M203-RM | U8410006 | - | - |

| M203-SM | U8410007 | |||||

20 | 3 | 0.125 | M208-RM | U8410019 | - | - |

| M208-SM | U8410020 | |||||

| 20 | 3 | 0.125 | M208H-RM | U8410018 | 2133 | U8770412 |

| 20 | 3 | 0.125 | M2055** | U8415013 | - | - |

| 30 | 6 | 0.25 | V213-BC-RM** | U8411022 | - | - |

*These transducers can only be used with the High Penetration software option.

**Delay line is not replaceable on these transducers.

Replaceable Delay Lines

Delay lines function as a protective buffer between the surface of the test piece and the transducer element.

Element | Delay Line | Maximum Thickness Measurement Limit* | |||||||

| mm | inches | Part | Item Number | Steel - Mode 2 | Steel - Mode 3 | Plastic - Mode 2 | |||

| mm | inches | mm | inches | mm | inches | ||||

| 13 | 0.50 | DLH-2 | U8770062 | 25 | 1.0 | 13 | 0.5 | 13 | 0.5 |

| 6 | 0.25 | DLH-1 | U8770054 | 25 | 1.0 | 13 | 0.5 | 13 | 0.50 |

| 3 | 0.125 | DLH-3 | U8770069 | 13 | 0.5 | 5 | 0.2 | 5 | 0.2 |

Additional Products

Couplants

Liquid couplant is almost always necessary to provide acoustic coupling between the transducer and the test piece. We offer various types of couplants to suit virtually all applications.

Calibration Test Blocks

Test blocks are necessary for the calibration of ultrasonic thickness gages and should be used to maintain and verify the accuracy, dependability, and reliability of ultrasonic measurements. Blocks are held to tighter tolerances than stated in ASTM E797 code. Metric test blocks are available.

Transducer Cables

A wide selection of transducer cables suitable for all ultrasonic thickness gaging instrumentation.

- Standard

- Waterproof

- Heavy Duty

- Teflon

- Armored PVS Jacket

- Armored Silicone Jacket

- Stainless Steel

45MG Product Introduction Video

.jpg)

Related Videos

Related Videos

45MG Drop Test

| 45MG User's Manual | English - 2.5MB |

| 45MG Getting Started Guide | English - 0.4MB |

| 45MG Ultrasonic Thickness Gage | English - 0.4MB |

Ελ. Βενιζέλου 7 & Δελφών, 14452 Μεταμόρφωση, Αθήνα, Ελλάδα |