EPOCH 650 on-board file report output (Bitmap format)

|

|

The EPOCH 650 is a conventional ultrasonic flaw detector with excellent inspection performance and usability for a wide variety of applications. This intuitive, rugged instrument is a continuation of the popular EPOCH 600 flaw detector with additional capabilities.

The large, full VGA transflective display combined with our patented digital high dynamic range receiver provides a stable, striking A-scan representation in any lighting condition. The EPOCH 650 is designed to meet the requirements of EN12668‑1 and allows a full range of standard and optional flaw detection features. Multiple onboard reporting tools and a comprehensive data filing system enable you to easily collect and report high quality inspection data. The rugged, ergonomic design allows use in nearly any inspection environment, while the flexible PerfectSquare™ pulser and highest number of digital filters in its class can tackle nearly any application.

The EPOCH 650 Digital Ultrasonic Flaw Detector combines Olympus’ industry leading conventional flaw detection capabilities with the efficiency of a highly portable, intuitive instrument. The EPOCH 650 flaw detector’s blend of efficient menus and direct access keys allows you to take advantage of the highest quality flaw detection platform with exceptional ease of use.

The EPOCH 650 is designed for use in nearly any inspection environment, from bench top testing in a laboratory to extreme outdoor and hazardous conditions. Designed for IP rating in either knob (IP66) or navigation pad (IP67) configurations, and tested to very high environmental and reliability standards, the EPOCH 650 allows users in any inspection environment to feel confident in both the performance and durability of the instrument.

The EPOCH 650 design is focused on providing a very high level of flaw detection with the simplicity of a basic instrument. The EPOCH 650 is designed to be ergonomic, intuitive, and practical for both experienced and novice ultrasonic inspectors.

The EPOCH 650 user interface is based on the industry leading EPOCH 600 flaw detector. The EPOCH 650 combines a simple menu structure for instrument settings, calibration and software feature adjustment, with the EPOCH brand’s hallmark direct-access key approach

for critical inspection functions such as gain and gate adjustment, screen freeze, and file save. Supported in multiple languages, the EPOCH 650 user interface is intuitive for any level of operator.

The EPOCH 650 features a full VGA (640 x 480 pixels) resolution display. The horizontal design of the EPOCH 650 optimizes the A-scan size and readability on this high quality display. Built with transflective technology, this VGA display provides excellent clarity in indoor, low lighting conditions using its powerful backlight, as well as in direct sunlight by using the ambient light as a pseudo-backlight.

The full screen mode feature enhances this vibrant display to provide the largest A-scan in an EPOCH series flaw detector!

EPOCH 650 DGS/AVG feature - Standard Screen mode

EPOCH 650 DGS/AVG feature - Full Screen mode

In order to accommodate different user needs and preferences, the EPOCH 650 is available in two hardware configurations:

The adjustment knob on the EPOCH 650 is used along with the CHECK and ESC keys to adjust parameter values in either coarse or fine increments. You have the ability to lock the knob to prevent accidental parameter value changes during an inspection. This configuration provides smooth value slewing for customers who prefer adjusting parameters using a knob. The knob configuration is designed to meet the requirements of IP66.

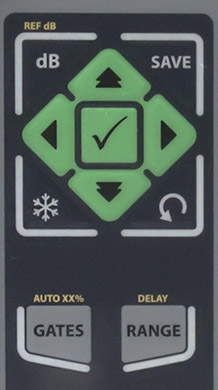

The EPOCH 650 navigation pad is a hallmark feature of the EPOCH flaw detectors. The up and down arrows on the navigation pad are used for coarse parameter adjustment, and the left and right arrows for fine adjustment. The navigation pad also contains additional functions and frequently used parameters such as gain, save, and the CHECK and ESC keys. The navigation pad configuration is designed to meet the requirements of IP67.

A – USB On-The-Go port

B – MicroSD card

C – DC power connector

D – VGA port

E – Digital I/O port

F – Transducer connectors (2)

G – Battery door

H – Pipe stand

The EPOCH 650 is a lightweight, portable flaw detector built to be rugged and flexible for nearly any inspection. Some key physical features include:

| nstrument Inputs/Outputs | USB Ports | USB On-The-Go (OTG) |

|---|---|---|

| RS-232 Port | Yes | |

| Video Output | VGA output standard | |

| Analog Output | 1 analog output (optional), Selectable 1 V/10 V Full Scale, 4mA max | |

| Alarm Output | 3 alarm outputs, 5 V TTL, 10 mA | |

| Trigger I/O | Trigger input, 5V TTL; Trigger output, 5V TTL, 10 mA max | |

| Encoder Inputs | 1-axis encoder line (quadrature - Corrosion Module mode only) |

| Environmental Ratings | IP Rating | Designed to meet the standards of the Ingress Protection (IP) rating number IP67 (navigation pad version) or IP66 (knob version) per IEC 60529-2004 (Degrees of Protection provided by enclosures – IP Code). The product design was confirmed to meet the IP rating by means of Olympus internal design verification test process that occurs prior to the release of the product to production. |

|---|---|---|

| Explosive Atmosphere | Safe operation as defined by Class I, Division 2, Group D, as defined in the National Fire Protection Association Code (NFPA 70), Article 500, and tested using MIL-STD-810F, Method 511.4, Procedure I. | |

| Shock Tested | MIL-STD-810F, Method 516.5 Procedure I, 6 cycles each axis, 15g, 11 ms half sine. | |

| Vibration Tested | MIL-STD-810F, Method 514.5, Procedure I, Annex C, Figure 6, general exposure: 1 hour each axis | |

| Operating Temperature | –10 °C to 50 °C (14 °F to 122 °F) | |

| Battery Storage Temperature | 0 °C to 50 °C (32 °F to 122 °F) |

| General | Overall dimensions (W x H x D) | 236 mm x 167 mm x 70 mm (9.3 in. x 6.57 in. x 2.76 in.) |

|---|---|---|

| Weight | 1.6 kg (3.5 lb), including lithium-ion battery | |

| Keypad | English, International, Japanese, Chinese | |

| Languages | English, Spanish, French, German, Japanese, Chinese, Portuguese, Russian | |

| Transducer connections | BNC or Number 1 LEMO | |

| Data storage | 100,000 IDs onboard, removable 2 GB MicroSD card (standard) | |

| Battery type | Single lithium-ion rechargeable standard | |

| Battery life | 15 h to 16 h (lithium-ion) | |

| Power requirements | AC Mains: 100 VAC to 120 VAC, 200 VAC to 240 VAC, 50 HZ to 60 Hz | |

| Display type | Full VGA (640 x 480 pixels) transflective color LCD, 60 Hz update rate | |

| Display dimensions (W x H, Diag.) | 117 mm x 89 mm, 146 mm (4.62 in. x 3.49 in., 5.76 in.) |

| Receiver | Gain | 0 to 110 dB |

|---|---|---|

| Maximum input signal | 20 V p-p | |

| Receiver input impedance | 400 Ω ± 5% | |

| Receiver bandwidth | 0.2 MHz to 26.5 MHz at -3 dB | |

| Digital filter settings | Thirty digital filter sets standard Seven EN12668-1:2010 compliant filters (0.2-10 MHz, 2.0-21.5 MHz, 8.0-26.5 MHz, 0.5-4 MHz, 0.2-1.2 MHz, 1.5-8.5 MHz, 5-15 MHz) | |

| Rectification | Full-wave, Positive Half-wave, Negative Half-wave, RF | |

| System linearity | Horizontal: ± 0.5% FSW | |

| Resolution | 0.25% FSH, amplifier accuracy ± 1dB | |

| Reject | 0 to 80% FSH with Visual Warning | |

| Amplitude measurement | 0 to 110% full screen height with 0.25% resolution | |

| Measurement rate | Equivalent to PRF in all modes |

| Calibration | Automated calibration | Velocity, Zero Offset Straight Beam (First Backwall or Echo-to-Echo) Angle Beam (Soundpath or Depth) |

|---|---|---|

| Test modes | Pulse Echo, Dual, or Through Transmission | |

| Units | Millimeters, inches, or microseconds | |

| Range | 3.36 mm to 13,388 mm (0.132 in. to 527.10 in.) @ 5,900 m/s (0.2320 in./μ) | |

| Velocity | 635 m/s to 15240 m/s (0.0250 in./µs to 0.6000 in./µs) | |

| Zero offset | 0 µs to 750 µs | |

| Display delay | -59 mm to 13,401 mm (-2.320 in. to 526.97 in.) @ longitudinal velocity in steel | |

| Refracted angle | 0° to 90° in 0.1° increments |

| Gates | Measurement gates | 2 fully independent gates for amplitude and TOF measurements |

|---|---|---|

| Gate start | Variable over entire displayed range | |

| Gate width | Variable from Gate Start to end of displayed range | |

| Gate height | Variable from 2 to 95% full screen height | |

| Alarms | Positive and Negative Threshold, Minimum Depth (Gate 1 and Gate 2) |

| Measurements | Measurement display locations | 5 locations available (manual or auto selection) |

|---|---|---|

| Gate (1, 2) | Thickness, Soundpath, Projection, Depth, Amplitude, Time-Of-Flight, Min./Max. Depth, Min./Max. Amplitude | |

| Echo-to-Echo | Standard Gate 2-Gate 1, Optional IF Gate Tracking | |

| Other measurements | Overshoot (dB) value for DGS/AVG, ERS (equivalent reflector size) for DGS/AVG, AWS D1.1/D1.5 A, B, C and D values, Reject Value, Echo to RefdB values | |

| DAC/TCG | Standard | |

| DAC points | Up to 50 points, 110 dB dynamic range | |

| Special DAC modes | Custom DAC (up to 6 curves), 20-80% View | |

| Curved surface correction | Standard OD or Bar correction for Angle Beam measurements | |

| Corrosion (optional) | Zero-cross measurement algorithm, V-Path correction, Single or Echo-to-Echo, Encoded B-scan |

The EPOCH 650 provides excellent quality ultrasonic performance. Based on the same digital architecture as

the EPOCH 600 and EPOCH 1000 Series, the EPOCH 650 provides flexible, powerful pulsing and receiving features to accommodate the needs of most flaw detection inspections.

The EPOCH 650 comes standards with powerful flaw detection capabilities, such as:

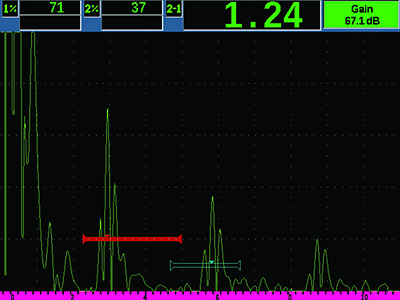

EPOCH 650 Echo-to-Echo with Gate Tracking

Dynamic DAC/TCG: Calculates signal amplitude as a percentage or decibel level compared to a DAC curve or a reference echo amplitude fixed at a time-varied gain. DAC versions include Standard, ASME 3, JIS, and Custom. Also includes several key features: dynamically adjustable DAC curves, switchable DAC and TCG views, custom DAC warning curves, and 20-80% DAC views.

DGS/AVG: This flaw sizing technique allows echo signals to be evaluated with a DGS/AVG diagram associated to

a particular type of probe and material. The DGS/AVG diagram illustrates the relationships between echo height, flaw size, and distance from the transducer.

AWS D1.1 and D1.5: Provides a dynamic reflector indication rating for various AWS weld inspection applications. This allows more efficient inspections by eliminating manual calculations.

EPOCH 650 Dynamic DAC/TCG Feature

Interface Gate: This optional third measurement gate enables real-time tracking of a variable interface echo in order to maintain consistent digital measurements.

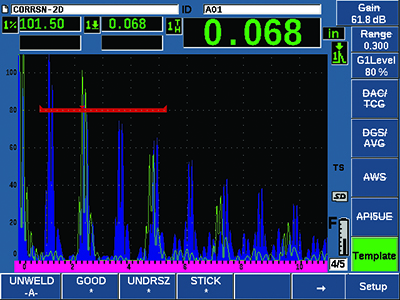

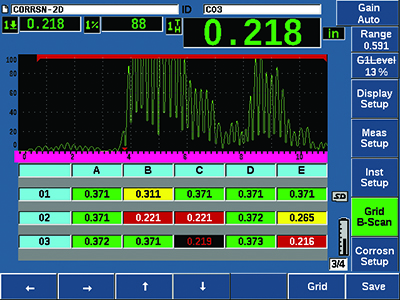

Corrosion Module: Simplified corrosion mode allowing automatic ultrasonic setups based on transducer selection, Automatic Gain Control (AGC), thickness gage measurement algorithm, V-Path correction, and transducer wear compensation using an automatic zero function (“Do Zero”). Also features color-coded Grid View and encoded B-scan.

EPOCH 650 Template Storage Feature

Template Storage: Allows on-screen comparison of a live waveform with a saved reference waveform. Saved templates can be dynamically toggled on and off with a single key press for fast waveform comparison. Excellent for spotweld analysis and other applications.

Backwall Echo Attenuator (BEA): Attenuates the backwall of an inspected part using the screen region defined by Gate 2.

API 5UE: Allows defect sizing according to API Recommended Practice 5UE. Uses the Amplitude Distance Differential Technique (ADDT) to measure the size of

potential defects during the prove-up process of OCTG pipe.

Waveform Averaging: This feature allows live A-scan averaging 2X, 4X, 8X, 16X, and 32X.

EPOCH 650 Corrosion Module Feature

The EPOCH 650 allows several methods of storing, archiving and reporting inspection and calibration data.

The instrument features up to 100,000 points of onboard memory, as well as video recording and review. It is also fully compatible with Olympus PC interface program, GageViewTM Pro. With quick file setup functions and flexible data management, logging and reporting inspection data is simple and efficient.

The EPOCH 650 features an onboard data logger for calibration and inspection file storage. The instrument comes with two primary file types: calibration (CAL) and incremental (INC) files. CAL files allows you to save a virtually unlimited number of parameter setups for fast and easy recall to live settings. INC files store multiple pieces of inspection data under a single file name for downloading and reporting by inspection.

The onboard data logger is enhanced by full featured corrosion-style data logger file types standard on the EPOCH 650. This feature includes the following data file types: sequential, sequential with custom point, 2-D grid, 2-D grid with custom point, 3-D grid, boiler, 2-D EPRI.

The EPOCH 650 is fully compatible with our PC interface program, GageViewTM Pro. You can download inspection data, review measurements on a PC, export measurements and calibration data to common spreadsheet programs, back up calibration and inspection data from the instrument, and perform basic operations such as instrument firmware upgrades and screen captures.

The EPOCH 650 utilizes an external microSD memory card (2 GB included, up to 64 GB supported) for both onboard and removable memory. Through removable memory, you are able to share files between instruments, as well as output reports in various formats. A second 2 GB microSD card is mounted to the PC board inside the instrument, and is responsible for all onboard data storage. In the event the instrument is damaged beyond repair, this microSD card can be removed at an authorized service center, allowing the operator to recover critical data from the damaged instrument.

The EPOCH 650 allows report generation on-board in a variety of formats. You can easily capture screen shots to the removable microSD card, as well as exporting saved data in .csv or .xml files. The instrument also features Bitmap report generation for single data points or entire files.

The EPOCH 650 comes standard with a video recording feature. You can capture up to 8 minutes of the live A-scan inspection data at 60 frames per second. This data can be reviewed on the EPOCH 650 or exported for review on a PC.

| EPOCH 650 Ultrasonic Flaw Detectors | English - 3.0 MB |

Ελ. Βενιζέλου 7 & Δελφών, 14452 Μεταμόρφωση, Αθήνα, Ελλάδα |